Water

ENVIRONMENT

Protection of the marine environment is a priority and an ongoing commitment. Our production site stands by the sea, and both the incoming raw materials and the outgoing products are shipped by sea: thus we have a duty of care for the environment that hosts our operations. Respect for the sea is ensured through a three-pronged approach: constant monitoring, prevention and control.

MONITORING

The sea area fronting the refinery is monitored by of seawater samples taken at different depths, to check the environmental parameters of the waters.

Marine biologists perform regular samplings and tests to support the plant’s chemical laboratory, equipped with highly sophisticated technologies.

Correctness of these readings is checked by several supervisory authorities, such as the Harbourmaster’s Office and the Ministry of the Environment.

Throughout the two-year period 2023-2024, the quality status of marine waters was found to be in the high range of the classification, highlighting a high level of water quality.

To assess the trophic state of the waters, a new parameter – specific to the seas surrounding Sardinia, has also been used: CAM (seawater classification) index based on specific algorithms for the different sea areas.

CAM index values for the sea surrounding Sarroch consistently show high quality of the seawater.

For the full data on seawater monitoring and quality, see our 2025 Environmental Statement

PREVENTION

Maritime transport is very important to Sardinia: the port of Cagliari is the third-ranking in Italy in terms of tonnes of cargo handled.

The Sarlux marine terminal with an average traffic of 800 ships a year, is a major contributor to this result.

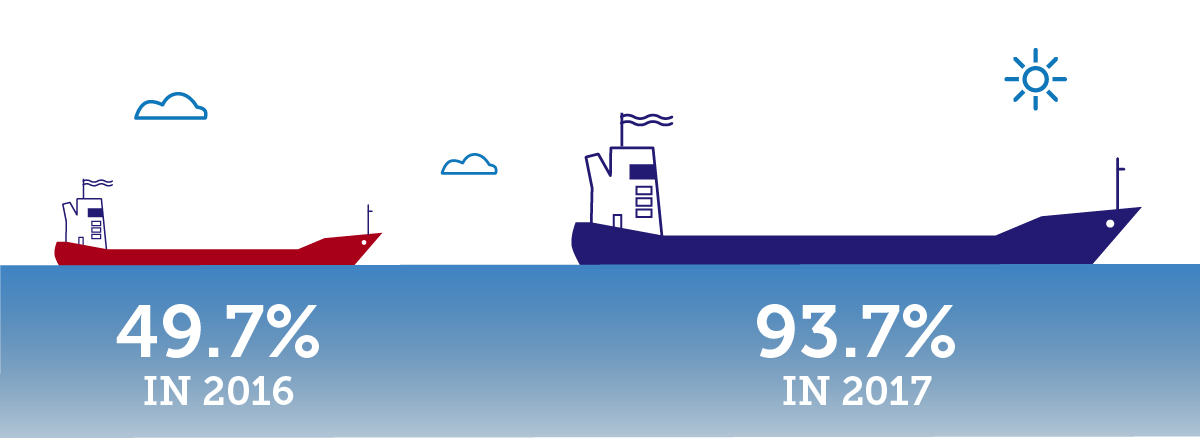

For several years now, we have implemented a strict vetting and control policy on the characteristics of all the crude oil and refined product tankships docking at our terminal.

In order to be admitted to the marine terminal, all incoming tankers must comply with stringent safety standards that conform to internationally recognised criteria and to additional requirements laid down over time by our Group.

Our policy is to screen each ship’s characteristics and history, to obtain a detailed ship profile. In addition, ships bound for our facility are carefully checked by specialist companies at the port of departure before sailing.

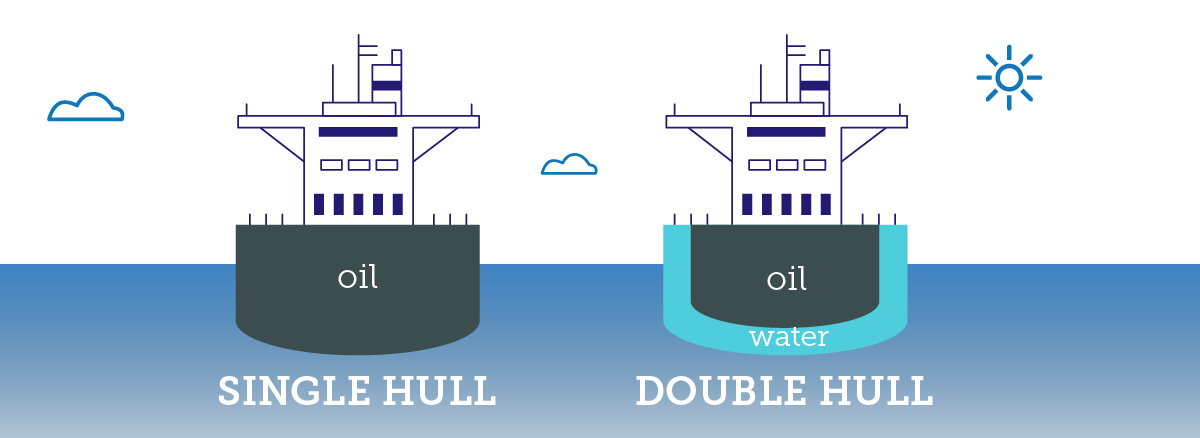

Since 2014, all ships docking at the Sarlux jetty must have a double keel, whether they carry crude oil or refined products (gasoline, kerosene, diesel fuels).

This requirement was introduced well ahead of the deadlines established by European Union regulations to ban the use of single-hull oil tankers, in order to prevent any spillages and avoid contamination of the sea.

Advanced control systems ensure the highest safety of all crude unloading and product loading operations; the vessels are boarded by independent qualified inspectors who check compliance with all the safety and marine environment protection requirements.

The reference standards for the checks are the “Minimum Safety Criteria” adopted in accordance with the ship inspection protocols established by the Oil Companies International Marine Forum (OCIMF), an organisation that promotes the safe and environmentally responsible operation of oil tankers, terminals and offshore support vessels.

Since 2000 the Group has decided to charter only ships that do not pass through

the Strait of Bonifacio, to further guarantee the protection and preservation

of the precious marine environment.

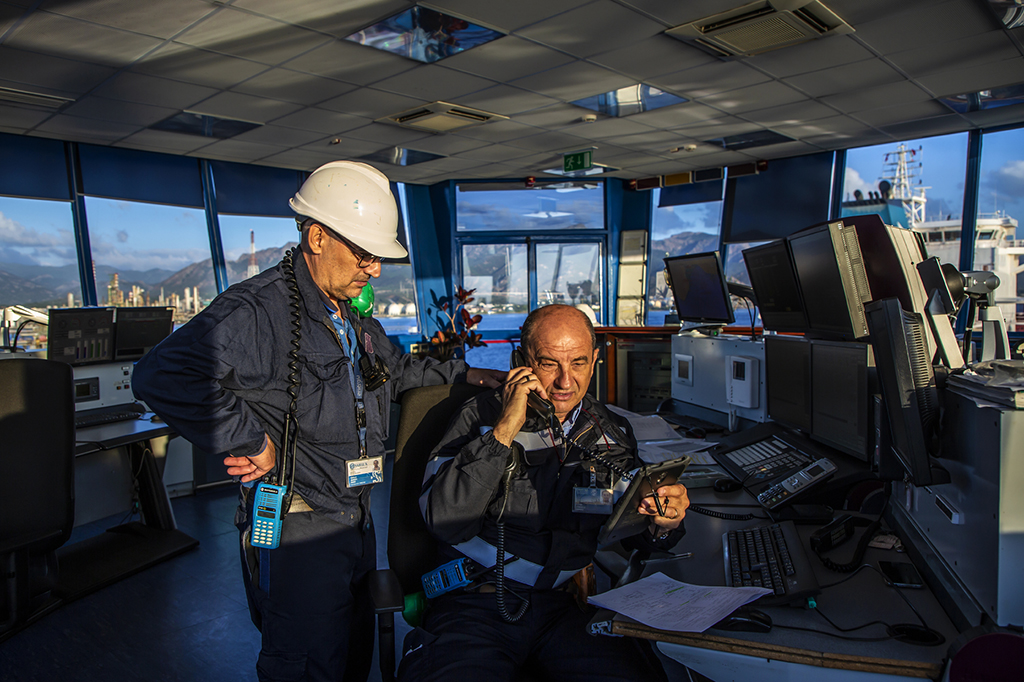

A dedicated operations centre which has been completely renovated and updated with the latest control technology, is manned and operational 24 hours a day, and is in continuous radio contact with the ships operating in the terminal, ensuring that all operations comply fully with all safety and environmental protection requirements.

The refinery also has a round-the-clock spill response system in place, with dedicated staff and vessels, guaranteeing fast response in the event of product spillages, in accordance with the Internal Emergency Plan, which also includes the Marine Pollution Prevention Plan.

Sarlux provides at no charge bilge and ballast water disposal services

to the ships docking at its marine terminal and to those that send their bilge water

from all Sardinian ports in tanker trucks.

FRESHWATER

Water is a precious resource for our refinery.

Our policy has long been to reduce our dependence on water from mains supply, to limit our use of the local freshwater resources.

At the Sarroch site, water is mainly used to produce steam for our processes (steam stripping, heat exchangers and power generation), to supply the fire prevention system, to replace cooling cycle losses and for civil use.

Water use is constantly monitored to optimize consumption and prioritize recovery and desalination.

Specifically, the contribution of water from desalination and internal recovery to meeting needs was approximately 74 percent.

The remainder comes from the Macchiareddu industrial consortium and is purified and potable, making it highly sustainable.

Since 2021, following optimisation measures in the water management system,

the percentage of fresh water sourced from third parties has become the least signi-ficant supply

compared to the other two main sources: seawater withdrawal and water reuse.

In 2018, in fact, we started to operate the largest new desalination plant in the Mediterranean.

In 2019, in April, the insertion of all sections of the new seawater desalination plant was completed, up to the unit’s maximum capacity: 500 m3/h. Following achievement of full capacity, since May, the old desalination units built in the 1990s, which are no longer energy efficient, have been shut down.

The desalinator was awarded the “Distinction” by the Global Water Awards 2018, by Global Water Intelligence, which recognises the best initiatives in the water, wastewater and desalination sectors through innovative technology adoption and sustainable financial models.

This is a major step forward in our drive for environmental sustainability, but to do even better we are making more investments to maximise water recovery from treatment plants.

Sources: Sarlux Environmental Statement 2025 and Saras ESG Report 2024